As the temperature hovered around 100 degrees on August 9, 2016, Texas A&M Transportation Institute (TTI) roadside safety device experts and a Texas Department of Transportation (TxDOT) transportation engineer gathered on a runway at the Texas A&M University RELLIS Campus. They were hoping to witness a historic crash test under TxDOT’s Roadside Safety Device Crash-Testing Program.

Their goal was to stop a vehicle traveling at 62 miles per hour after it plowed through the nose of a short-radius guardrail at a 25-degree angle but before it ran into a ditch directly behind the guardrail. (What’s a short-radius guardrail? See the sidebar to this article.)

“Engineers from around the country have been trying to solve this problem for decades,” says TTI Assistant Agency Director Dean Alberson, who’s also head of TTI’s Crashworthy Structures Program.

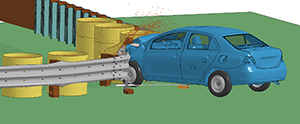

TTI Research Scientist Akram Abu-Odeh had reason to believe that his new design would be successful. To deal with the crash-through problem, Abu-Odeh used sand-filled barrels and a cable barrier strategically placed and anchored behind the railing. With the help of advanced computer simulation, Abu-Odeh altered location and placement of the components until the device passed the test on his computer screen.

“The sand barrels and the cable are both needed to absorb and dissipate the energy of the 5,000-pound pickup truck required for the test,” Abu-Odeh explains. “Using readily available components is important in getting this design implemented. But it first has to pass this full-scale test.”

When the truck slammed into the guardrail and then hit the barrels, sand exploded and rained down on the crash site. But the truck came to a safe and almost immediate stop, instead of heading into the steep ditch, located just 5 feet from the guardrail.

“High-speed crashes into a short-radius guardrail with a steep slope behind it happen on our roadways more often than people realize. And they are often fatal or lead to serious injury,” says Christopher Lindsey of TxDOT’s Design Division. “Because of the success of this test, I think we’re well on our way to issuing a standard in Texas. We could be seeing this short-radius guardrail treatment in use soon, perhaps in a year’s time.”

Where’s Your Sign?

It’s not uncommon to see signs mounted on top of concrete barriers, especially in work zones. But what happens when a crash occurs at the precise location where the sign is mounted?

In another project supported by TxDOT, Abu-Odeh developed numerous crashworthy sign-post design concepts. He tested them first with the aid of computer simulation, and TxDOT selected four concepts for further testing. All four were crash-tested using the American Association of State Highway and Transportation Officials (AASHTO) Manual for Assessing Safety Hardware (MASH) Test Level 3 guidelines. The three performing the best were the sliding base with chute design, the thinner-wall post with 3-inch-long slots, and the hinge and sacrificial pin design.

“The shoulder width on urban roadways is often too narrow to install the roadside signs needed to convey important information to motorists. This is especially true for signs in the median,” explains TxDOT Research Project Manager Wade Odell. “The results of this research are significant because there is a real opportunity to install signs on the concrete median barrier in order to ensure safety in the event a vehicle crashes into that barrier.”