Alkali–silica reactions (ASRs) cause cracking issues in precast concrete bridge structures. In collaboration with Texas A&M Transportation Institute (TTI) Assistant Research Scientist Kai-Wei Liu, TTI Senior Research Scientist Anol Mukhopadhyay developed two ASR test methods now accepted as American Association of State Highway and Transportation Officials (AASHTO) standards, as well as a four-step process for formulating ASR-resistant concrete mixes.

Mukhopadhyay manages TTI’s Rigid Pavements Program and supervises the Concrete Innovation Laboratory in the Center for Infrastructure Renewal on The Texas A&M University System’s RELLIS Campus. He is nationally and internationally recognized as a concrete durability expert.

“Developing the test methods and seeing them accepted as AASHTO standards were rewarding for me and my team,” says Mukhopadhyay. “AASHTO’s recognition enables the methods to reach a wider audience of concrete mix producers and owners, who can follow the steps to create their own ASR-resistant mixtures.”

“AASHTO materials standards are recognized as vetted by experts in state departments of transportation — with academia and industry involvement — to provide materials protocols that transportation agencies can adopt confidently,” says Georgene Geary, retired materials engineer, currently a consultant for AASHTO and former vice chair of the AASHTO Materials Committee.

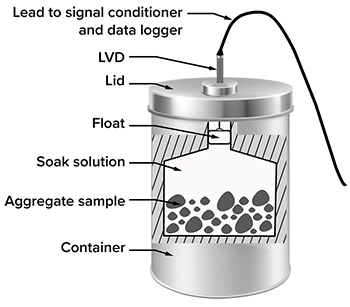

The first ASR test method, volumetric change measuring device (VCMD), is listed by AASHTO as the Standard Method of Test for Determination of Composite Activation Energy of Aggregates due to Alkali–Silica Reaction (Chemical Method) (AASHTO T 364). This method measures how an aggregate — similar in makeup to portland cement concrete — reacts with a simulated pore solution.

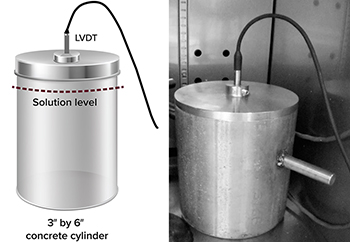

AASHTO lists Mukhopadhyay’s second ASR test method, accelerated concrete cylinder testing (ACCT), as Accelerated Determination of Potentially Deleterious Expansion of Concrete Cylinder due to Alkali–Silica Reactivity (AASHTO TP 142-21). This method validates concrete mixes by offering further ASR-resistant testing. Mukhopadhyay applied the ACCT-based method to fly ash — a coal combustion product — and found that the ASR test method performs similarly fast, reliable tests on reactivity like the VCMD-based method.

Combining both methods resulted in a four-step mix process to reduce ASR’s impact on concrete in bridges. The steps are as follows:

Renewal’s Concrete Innovation Laboratory.

-

Step 1: Determine the CAP (a measure of aggregate reactivity) and the aggregate threshold alkalinity (THA) by the VCMD method. A standard relationship between reactivity and THA has been developed based on several aggregate tests, which can be used to assign THA for an aggregate with known reactivity.

-

Step 2: Select suitable mix design controls depending on the aggregate reactivity and THA, and then estimate the concrete pore solution alkalinity (PSA). Mukhopadhyay and Pravin Saraswatula, a TTI engineering graduate student worker, developed an easy-to-use tool to estimate PSA.

-

Step 3: Make a mix design adjustment (if needed) based on the THA–PSA relationship. PSA needs to be below THA to mitigate ASR.

-

Step 4: Conduct mix design validation using the ACCT method. The expansion of the tested concrete cylinder should be less than or equal to 0.04 percent.

A leader in ASR-resistant concrete research, Mukhopadhyay coauthored the technical paper “An Innovative Approach to Fly Ash Characterization and Evaluation to Prevent Alkali–Silica Reaction” in the July 2019 issue (Vol. 116, No. 4) of the American Concrete Institute’s (ACI’s) ACI Materials Journal and “Innovative Approach for Formulating ASR-Resistant Mixtures” in the December 2018 issue of ACI’s Concrete International.

“Having easy access to ASR test methods can help support the construction and longevity of bridges by making long-lasting, durable concrete, reducing costs for repair and maintenance, and ensuring safety for travelers,” Mukhopadhyay says.