What We Do

Infrastructure Protection

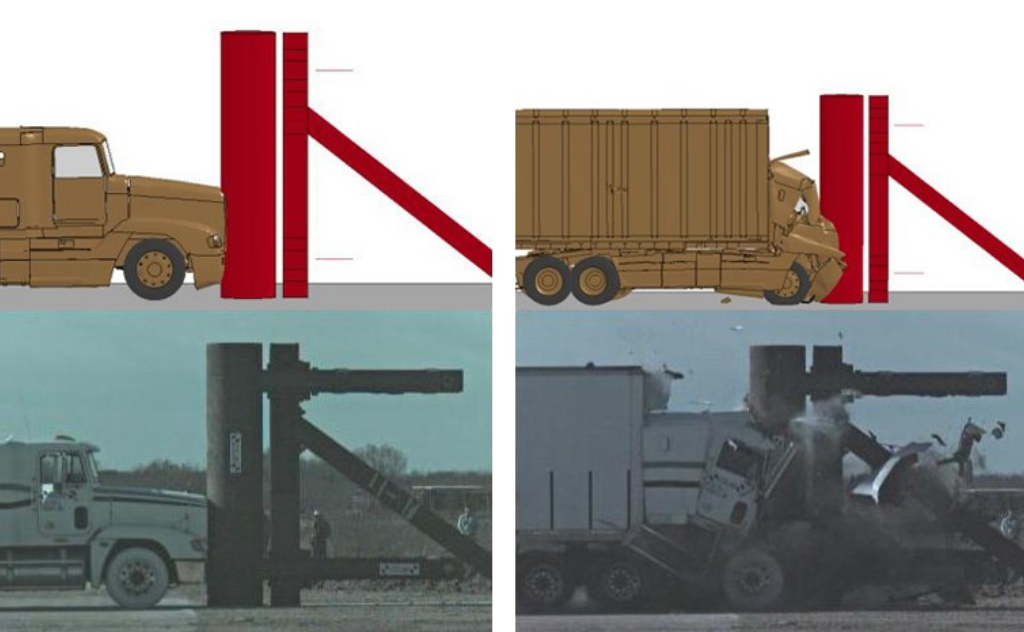

We protect people and infrastructure by developing and testing protection devices such as gates, perimeter fences and bollards. Through engineering analysis, finite element computer simulation and testing of these devices, we advance infrastructure and perimeter protection.

Roadside Safety

We prevent serious injuries and fatalities from roadway departure crashes by designing and testing roadside safety devices and developing roadside design guidance.

Proving Ground

Our Proving Ground is an ISO 17025 accredited laboratory that tests and evaluates roadside safety and infrastructure protection devices to various worldwide standards.

Adaptive Equipment

We enable drivers with disabilities by providing quality control checks and follow-up inspections of vehicles modified with automotive adaptive equipment.

Our Focus Areas

Security Barriers, bollards & fences

Extensive experience with designing and testing anti-ram devices.

Forced Entry Resistance

Testing resistance of fence systems against forceful penetration.

Low-speed protective devices

Crash test-based penetration rating of bollards per ASTM F3016.

Modeling & Simulation

Expertise in full-scale impact simulations using finite element analysis.

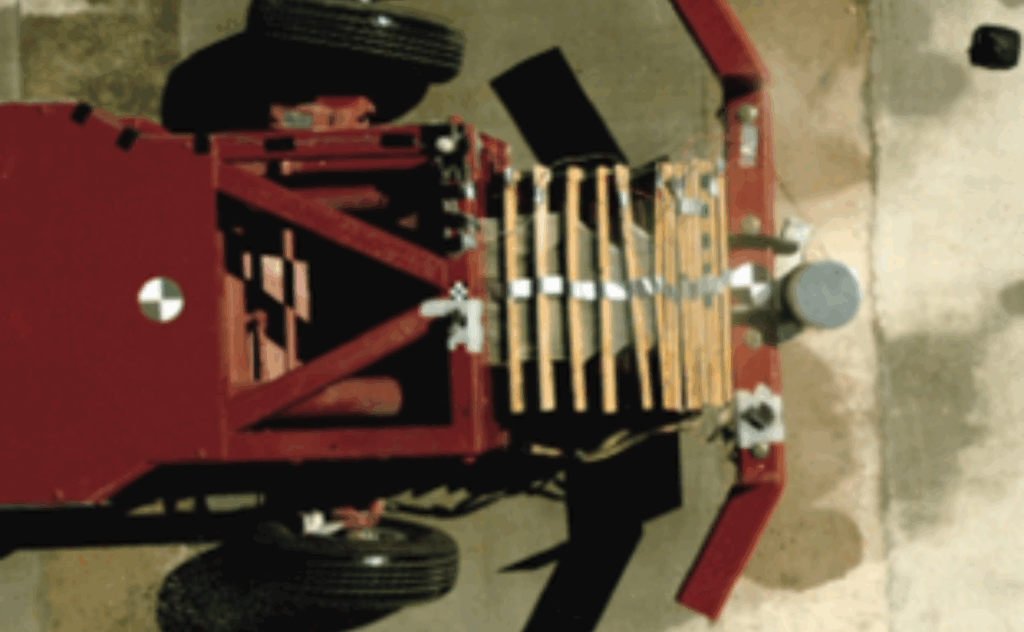

Industrial Guardrail testing

Crash test-based rating of industrial protection devices per ANSI MH31.2.

roadway Friction Measurement

ISO 17025 accredited to perform calibration, correlation and evaluation of roadway friction measurement systems.

Structural Design & analysis

Extensive experience and expertise in structural design and analysis of roadside safety and infrastructure protection devices.

Full-scale crash testing

Full-scale crash testing to evaluate roadside safety and perimeter security devices, using vehicles ranging from motorcycles to 18 wheelers.

Adaptive vehicle control

Evaluate structural integrity and safety of vehicles modified for use by disabled drivers.

3D scanning & reverse engineering

Finite element vehicle model development via 3D scanning and reverse engineering.

Our Work

Electric Vehicle Testing

The number of electric vehicles within the vehicle fleet continues to increase. Characteristics of electric vehicles have demonstrated compatibility issues with roadside hardware. TTI is conducting research to develop roadside safety solutions that are compatible with these emerging vehicle types.

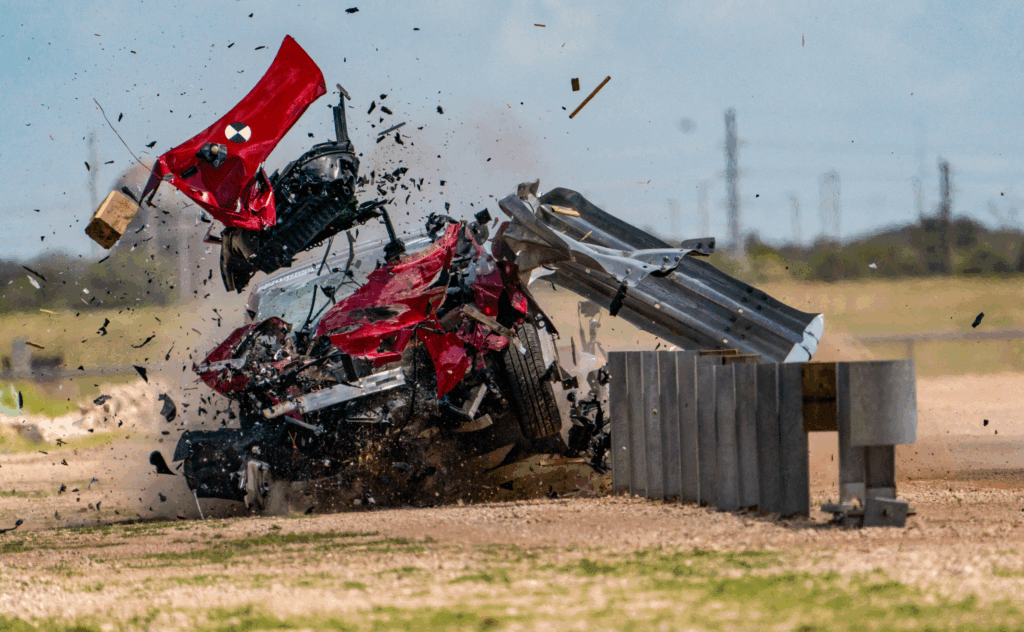

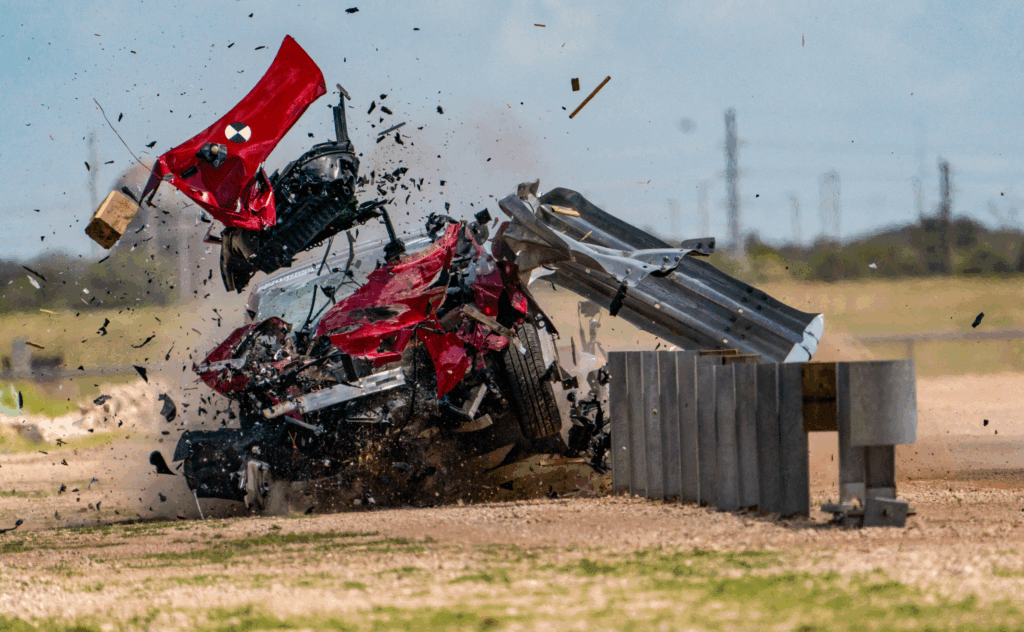

Infrastructure Protection

Threats to key infrastructure and facilities such as embassies, power plants, national labs, etc. require securing the perimeter using infrastructure protection hardware. TTI designs, develops, and crash tests devices, such as security gates, fences, wedges, bollards, etc. to protect these facilities.

Motorcyclist Impact Safety

Motorcycle run-off-road crashes represent a significant number of fatalities and serious injuries annually. TTI researchers are developing roadside safety hardware that accommodates motorcyclists without compromising motorist safety.

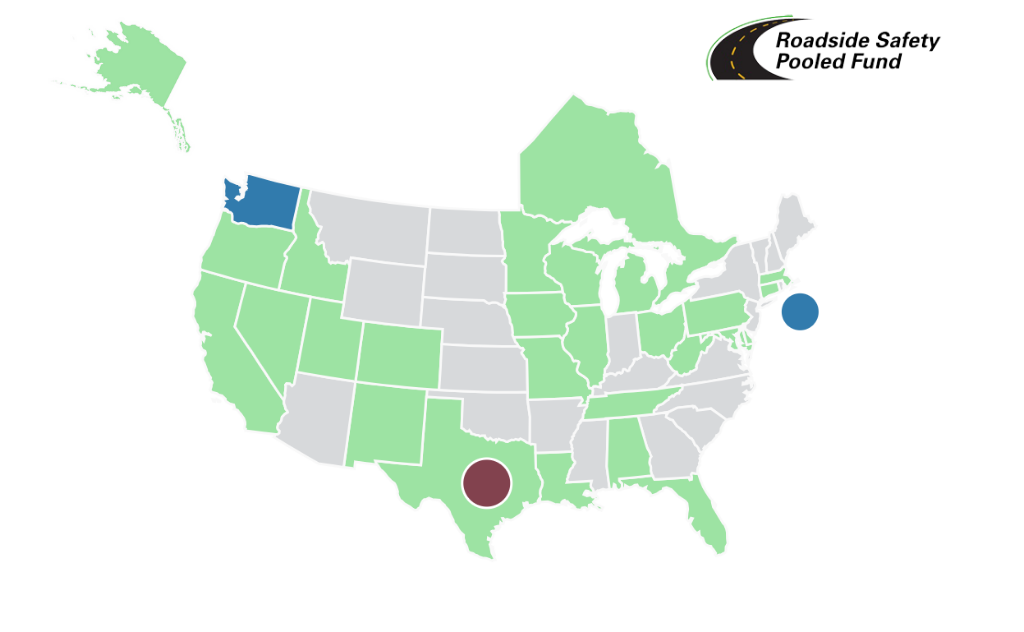

Roadside Safety Pooled Fund

Roadway departure crashes account for roughly half of highway fatalities each year. State departments of transportation pool their limited resources to address common roadside safety problems. TTI addresses these problems through research, development, and crash testing of innovative roadside safety solutions.

Industrial Guardrail Testing

Large distribution centers are a vital component to our global supply chain. Movement of goods throughout warehouses poses a safety risk to workers and infrastructure. TTI crash tests and evaluates the structural adequacy of safety hardware for impacts with forklifts and other lifting devices.

Roadside Safety Guidelines

Proper use and placement of roadside safety features are crucial for maximizing their effectiveness. As the vehicle fleet and safety evaluation criteria continue to evolve, ongoing research is needed to ensure compatibility with roadside safety hardware. TTI leads research and guideline development to ensure roadside safety measures remain effective and state-of-the-art.

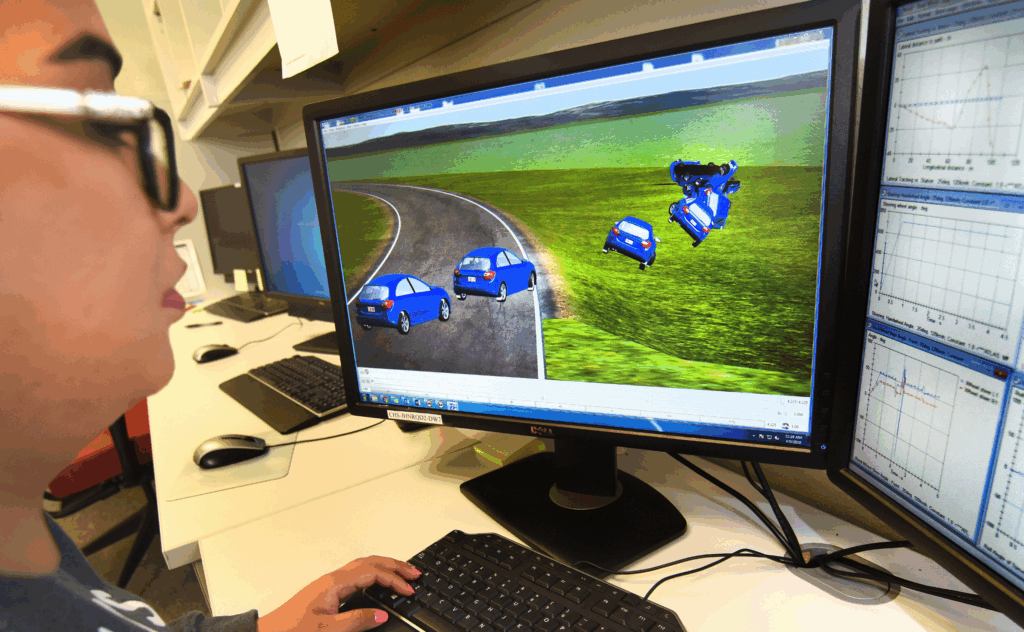

Modeling and Simulation

The complexity of vehicle impacts makes design of roadside safety and physical security hardware challenging. Modeling and simulation tools such as finite element analysis enable design alternatives to be investigated in a cost-effective manner. TTI researchers have extensive experience in modeling and simulation for evaluation of the impact performance of safety and protection hardware.

Crowd Protection

Large crowds are vulnerable to intentional and unintentional impacts by motor vehicles. TTI researchers design and evaluate protection devices such as pedestrian bollards and street furniture to shield crowds from potential threats.

The Team

Roadside Safety and Physical Security

Lance Bullard

Senior Research Engineer

Division Head

(979) 317-2877

[email protected]

Infrastructure

Protection

Nauman m. Sheikh

Research Engineer

Program Manager

(979) 317-2695

[email protected]

Roadside

Safety

Roger p. Bligh

Senior Research Engineer

Program Manager

(979) 317-2703

[email protected]

Proving Ground

Support

Bill Griffith

Research Specialist IV

Program Manager

(979) 317-2684

[email protected]