With roadway construction projects such as bridge construction, time and money are both at a premium. Mistakes may not only set the timeline back but stretch already strained budgets as well. Electrical resistivity tomography (ERT) is becoming a popular method to study the subsurface of a construction project area in a nondestructive way. ERT scans can help engineers determine not only where to drill but, more importantly, where not to drill.

ERT is a noninvasive geophysical method that provides an image of the electrical resistivity structure in a vertical plane beneath a linear array of metal electrodes planted in the ground and connected by a multicore cable. The method provides a snapshot of the subsurface for geophysical testing that occurs at large-scale construction projects.

“Much like a medical imaging specialist would try to interpret an image to find a broken bone, we do the same thing in geophysical images,” explains Mark Everett, Howard Karren Endowed Professor of Geophysics at Texas A&M University. “We try to make diagnoses such as what the material is, if there’s any kind of moisture in the ground, and if there’s any type of infrastructure down there. Then we convey that information to an engineer who can investigate further as needed. I’ve always said that the most important task of geophysics is to put an ‘X’ on the map.”

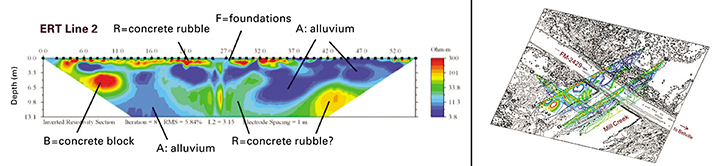

This method was put into practice recently at a new bridge construction project for the Texas Department of Transportation (TxDOT) on FM 2429 near Bellville, Texas. In the past, during times of high-water discharge, scouring of the stream bed occurred around the existing foundations near the south bridge abutment. Concrete fragments and other large debris were placed periodically into the scoured area as a remediation effort. The new bridge was being built immediately to the east of the existing bridge. However, the concrete debris proved to be a hazard to excavation of the new foundations.

“TxDOT wanted to build a new bridge with new foundations. But the previous scour hole had been filled with concrete rubble, so they could not easily excavate to put in a new foundation,” Everett says. “What they wanted ERT to do is find out how much concrete was down there. Because when they started digging it out, they just ran into more concrete, and it had the potential to be a costly nightmare. What they did in the end (after the testing) was to move their foundation by 20 feet into an area where the geophysics imaging told us there was no concrete. This guided them to redesign the bridge, actually.”

Another advantage of ERT is speed. The tests were performed in a few hours versus many more that would have been required if heavy machinery were used to move the concrete rubble.

The research team also conducted an ERT project on an interchange project on I-45 near Huntsville and measured a long section of highway in El Paso that took several days.

“ERT testing helped us identify areas with shallow water,” says Texas A&M Transportation Institute Research Engineer Darlene Goehl, who worked on the I-45 project. “These conditions are not easily identified through traditional design methods and can lead to construction delays and costly change orders. Identifying these areas and designing to mitigate the potential water damage to the new pavement will save time and money.”

“The accuracy is very good with respect to infrastructure,” Everett adds. “We’ve managed to successfully address the problems presented to us thus far. Looking deep with ground-coupled GPR [ground-penetrating radar] in areas with clay soils is often hit or miss, but I’ve found ERT to be pretty robust.”