Using recycled materials on roadways has been standard procedure in construction for several decades. The challenge lies in having a practical mix design process — think of it like a recipe, selecting the right ingredients and proportions — that agencies responsible for highway infrastructure can rely on for guidance.

The Texas Department of Transportation’s (TxDOT’s) Balanced Mix Design (BMD) Project is like a test kitchen where researchers experiment with tools that can help produce mixture recipes to build better roadways. The project is a collaborative effort by TxDOT, the Texas A&M Transportation Institute (TTI), The University of Texas at Austin’s Center for Transportation Research, The University of Texas at El Paso’s Center for Transportation Infrastructure Systems, and contractors and material suppliers from the Texas Asphalt Pavement Association.

“We’re currently developing a new mix design process that will provide more economical, high-quality and longer-lasting asphalt mixtures,” explains TTI Executive Associate Director Jon Epps, a principal investigator on the project. Epps leads TTI’s Pavement, Materials and Constructed Facilities Group. “And we’re prioritizing using more recycled materials — like reclaimed asphalt pavement [RAP] — whenever possible. That’s better for the environment because it reduces the overall carbon footprint of roadway construction, rehabilitation and maintenance operations.”

In the project currently underway, researchers are testing potential mixtures under real-world conditions (e.g., severe weather, traffic loads, aging over time, etc.) using a variety of recycled materials, including RAP. Testing is occurring in the laboratory and at 12 field projects across Texas. Each field project is its own experiment — involving one-lane strips of road (test sections) paved with a standard mixture (the control) and mixtures created via tools developed for the new BMD method. To date, the team has constructed six field projects, including two each in TxDOT’s Atlanta and San Antonio Districts and one each in the Yoakum and Paris Districts.

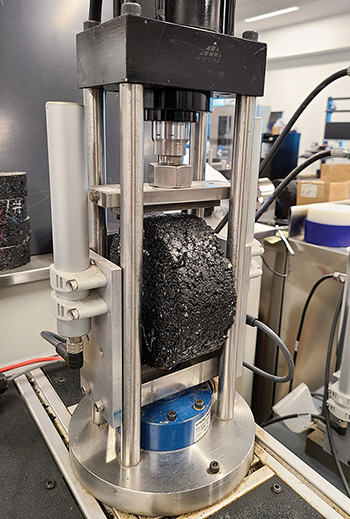

TTI is conducting associated mixture testing at the Asphalt Innovation Laboratory in The Texas A&M University System’s Center for Infrastructure Renewal (CIR), focusing on the new indirect tension asphalt cracking test and ideal shear rutting test to assess each mixture’s resistance to cracking and rutting, respectively. Successful field projects to demonstrate these tests and their ties to performance are the first step in revising asphalt mixtures using the BMD method.

“Building on the current TxDOT BMD specification makes it possible to engineer improved asphalt mixes,” says TTI Assistant Transportation Researcher Haydar Al-Khayat. “I’m very excited to be a part of the team and very confident that the outcomes will make a difference in producing longer-lasting roadways.”

TxDOT spent nearly $1.5 billion on roughly 20 million tons of asphalt mixtures during this past construction season. Ensuring a thorough approach to improving asphalt mixtures can reduce the construction and maintenance costs associated with road building by creating longer-lasting, more environmentally friendly roads. And better roads can encourage economic growth. For example, if agencies can extend pavement life by one year, the savings could potentially reach $160 million per year.

“The TxDOT BMD initiative will provide mix designers with the tools to design asphalt mixtures that are more durable,” TxDOT Flexible Pavements Section Director Enad Mahmoud says. “The BMD framework is an excellent tool to responsibly use recycled materials and adjust aggregate and asphalt grade/content to optimize mix performance.”