The National Traffic and Motor Vehicle Safety Act of 1966 introduced a new concept to motorist safety: the forgiving roadside. A year before that act was implemented, engineers at the Texas A&M Transportation Institute’s (TTI’s) Proving Ground Research Facility developed and crash-tested breakaway sign supports — just one example of the new philosophy then being put into practice. The TTI-tested sign supports quickly became a staple along the nation’s new Interstate Highway System.

“The breakaway system allowed a post to safely break away from its base when struck, preventing motorists from being killed or seriously injured in many cases,” explains Lance Bullard, head of TTI’s Roadside Safety and Physical Security Division. Numerous other safety devices were developed and tested, including crash cushions, concrete barriers, guardrails and cable barriers. Today, safety devices certified by TTI are on numerous roadways in the nation.

In 2001, TTI began crash-testing and designing bollards and other perimeter security devices for the U.S. State Department for use at embassies, consulates and military bases around the world. And now, researchers are preparing for low-speed bollard crash testing following a recently approved standard designed to improve storefront safety.

Located on 2,000 acres with 3.5 miles of paved runways, the Proving Ground has hosted thousands of full-scale crash tests. The facility is also home to numerous other permanent programs and equipment that, taken together, ensure our nation’s roadways will continue to be safer.

The Center for Transportation Computational Mechanics

Using sophisticated computer simulation and impact analysis software, researchers can predict the performance of roadside safety and perimeter security devices before an expensive, full-scale crash test is conducted. Researchers use a 3-D scanning device, called a FARO® Edge, to scan each individual vehicle part. “Because of our simulation capabilities, we are able to do a lot more than just crash testing,” Bullard explains. “We can create a virtual connected vehicle and infrastructure test bed without having to actually build it first — which saves money, time and resources.”

Toll Gantry

Congress has required that by 2016 the tolling industry develop interoperability standards allowing locally issued toll tags to work anywhere in the nation. “We’re testing a possible solution from two equipment manufacturers,” explains TTI Associate Research Scientist Roberto Macias. “We’re using the radio-frequency identification toll tags from various agencies and determining if the tested products can read them and if the vendors can be tied together.”

TTI conducts its testing by sending vehicles equipped with various toll tags through a toll gantry equipped with the transponders from the manufacturers. Macias says the project is halfway completed, with phase two beginning this summer.

Connected Transportation Initiative

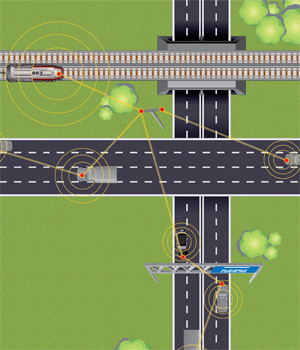

TTI’s Connected Transportation Initiative, which covers all modes of transportation, is paving the way toward a future where cars can reliably communicate with each other and the roadside infrastructure.

“We’ve been selected to conduct several large, innovative Texas Department of Transportation [TxDOT] projects, and we’re working on others with Battelle Memorial Institute and the University of Michigan,” says TTI Associate Research Engineer Rajat Rajbhandari, who heads up the connected vehicle test bed.

TTI’s research will examine ways to solve the problem of wrong-way driving, as well as investigate the potential for truck platooning, which enables connected commercial vehicles to safely, efficiently travel close together to save time and energy. Using advanced technologies, researchers are also exploring opportunities to enhance transit, bicycle and pedestrian safety.

Vehicle Detection Testing

To improve reliability and accuracy, TTI researchers are testing new vehicle-detection products for use at signalized intersections. Many of these new products have not been fully vetted, and TTI offers the space to replicate a large, high-speed urban intersection. The new types of vehicle-detection devices are designed to be more accurate, less costly and less intrusive to the motoring public.

“The Proving Ground allows us to test the new products in all kinds of weather conditions, day and night,” says TTI Research Engineer Dan Middleton, who’s conducting the research on behalf of TxDOT.

Adaptive Vehicle Control

Individuals with physical disabilities need special equipment to safely operate their vehicles. Working with the Texas Department of Assistive and Rehabilitative Services, TTI makes sure the equipment is installed properly, the vehicle is structurally sound, and safety is not compromised due to modifications of the accelerator, brake and other vehicle components.

The Central/Western Field Test Center

Since 1971, TTI has evaluated and calibrated pavement friction trailers (skid rigs) used by 25 state departments of transportation. The center ensures that the skid rigs, which test the friction characteristics of pavements, are working properly and comply with American Society for Testing and Materials standards.